LengLiang is with the working condition of dry fan coil units similar to one end of the induction device, it had already been popular in Europe for decades, the main reason is that it offers outstanding energy-saving benefit, completely mixed indoor air distribution and comfort, good indoor air quality and mute operation effect, is a very potential air conditioning technology, conforms to the development trend of world energy conservation and carbon reduction。

1. Working principle of cold beam air supply system

The cooling beam air supply system is equivalent to a gas-water parallel system in terms of indoor load heat exchange and heat transfer. Cold beam air supply port (hereinafter referred to as cold beam) is heat exchange by the "convection" and "radiation" effect caused by the temperature difference between the heat load of space (including the human body) and the cold beam panel. At the same time, the cold beam sends out dry cold air which also contributes to the evaporative cooling of the human skin surface. Therefore, cold beam is an air conditioning supply system which combines ice water to provide cold energy to control the temperature and uses the temperature difference of air supply to form convection circulation and steam pressure difference.

The cold beam is a dry coil whose main body is a finned cold water coil that allows air to pass through the fins to achieve cooling effect. It is supported by aluminum shells on the left and right sides and looks like a beam.

According to whether there is outdoor air supply, cold beam is divided into active cold beam and passive cold beam two forms.

Active cold beam refers to the air circulation power is supplied by external forced air supply, the formation of air induction process inside the cold beam, the use of forced convection to cause heat transfer between air and coil equipment. Active cold beam is mainly composed of shell, nozzle, primary air connection tube, heat exchanger (namely coil), panel and other parts. The summer air handling process for: from the outside and the air conditioning box processed in a dry and cold air through the nozzle at high speed, into the LengLiang, according to the venturi effect, when the high-speed flow of air through the obstacle in the obstacle of the lee side above will form a negative pressure near the port, resulting in a adsorption, induction of indoor of secondary air at low speed after cold tube. The cooled air mixes with the main stream to form a mixture of air that is fast enough to be below the temperature of the room. The mixed air flows through two closed diversion channels to form an attached jet that flows along the ceiling and then enters the room to cool the indoor air. After the same cycle, the heat of the room is taken away by the cooling coil, thus playing the role of cooling. In winter heat exchanger flow is hot water, cold beam played a heating role. The schematic diagram is shown in Figure 1.

Active LengLiang is small in size, compact structure, can significantly save architectural space (especially in height), and each LengLiang cabin, return air mouth, make the ceiling neat and beautiful, concise and lively, the end of the work under dry condition, uniform air distribution, improve the indoor air quality and thermal comfort, the device itself without any moving parts, interior noise is extremely low, Greatly improve the working environment. In addition, the active cold beam is generally equipped with a condensate tray under the coil, once the cold water temperature is below the dew point temperature condensation, condensation water can be collected by the condensate tray.

Passive cold beam system is an air conditioning system integrating refrigeration and heat exchange functions. It is mainly used to remove most of the sensible heat load in the room. Meanwhile, it also needs a separate primary air system for ventilation and humidity regulation. Passive cold beams are mainly composed of boxes, perforated panels and water coils with flanges and aluminum fins. They are usually suspended above the ceiling and cooled by natural convection. The cold beam system combines the advantages of comfort, low noise, energy saving and low maintenance. The schematic diagram is shown in Figure 2.

The advantages of passive cold beam and active cold beam similar to the use of high temperature circulating cold water in the cold beam coil, the host running at high cold water temperature, can improve the energy efficiency ratio and reduce energy loss. At the same time, the fresh air of the passive cold beam system is only used to adjust the humidity, which can save a lot of electric energy of the centralized processing unit and further achieve the effect of energy saving. However, because passive cold beams mainly rely on natural convection to allow airflow through the coils, the unit cooling capacity depends on the heat transfer capacity of the coils, and its performance is lower than that of active cold beams. In addition, when the body is installed in an unreasonable position, cold air may be directly blown to the object under it, resulting in a blowing sensation.

Two, the characteristics of cold beam air supply system

2.1 Advantages of cold beam air supply system:

(1) Wide range of capacity, cold beam has high cooling and heating capacity.

(2) Easy installation, cold beam equipment can be easily integrated into a variety of materials in the ceiling.

(3) Low noise, after special treatment of the nozzle in the maximum effect while maintaining the minimum noise.

(4) No motor, energy saving.

(5) Adaptability, cold beam equipment can have different lengths and widths, which makes the cold beam almost applicable

On all ceiling.

2.2 Disadvantages of cold beam air supply system:

(1) the initial investment is high, and condensate will be generated when out of control.

(2) The design of the external wall structure should avoid the condensation phenomenon caused by the leakage of hot and humid outdoor air and contact with the cold beam due to poor air tightness.

(3) Because the coils of the cold beam system are dry coils, there is a risk of condensation in the indoor places with large latent heat load.

(4) It should not be used in places with higher requirements for indoor air change times or more indoor pollution sources

Cold beam system.

Design of cold beam air supply system

3.1 Air treatment of cold beam

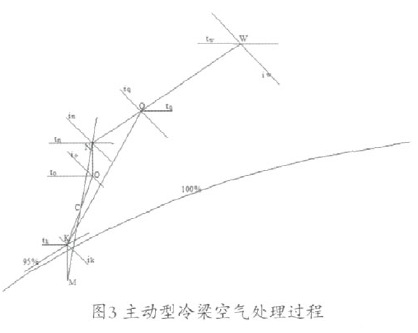

The primary air of the cold beam system is usually fresh air. If necessary, part of the return air can be used. The new return air mixture can save energy. But after the return air is used, the air duct system will be more complex, the investment will increase, and the economy of using the return air is not obvious, so most of the projects do not set the return air duct. The cold beam system can generally adopt high speed air supply, so the size of the machine room and the pipeline section are smaller than the all-air system (the pipeline section is only 1/3 of the all-air system), saving building space, ensuring the fresh air demand of each air conditioning area, and good sanitation. The new return air mixed air treatment process of cold beam system is shown in Figure 3:

First, the outdoor fresh air is mixed with the indoor return air to obtain the state point Q, which is cooled from the mixing point Q to the dew point K of the machine. The air supply state point O is obtained along the indoor isohygroid line by the air supply temperature difference δ T 0. The state points K and O are mixed to point C, and the indoor state point N is reached along the indoor air heat humidity ratio line.

Design steps of cold beam:

(1) The indoor state point N is passed on the enthalpy and humidity diagram, and then the supply air state point O is determined by the supply air temperature difference δ T 0.

(2) From the mixing ratio of the new return air, the point Q after mixing is obtained; Q K is the treatment process after the mixing of the new return air; the wet load that the mixed air must bear is W=L m(d n-d K); d K is the moisture content; d n is the air quality after the mixing of the new return air; d K is obtained from the above equation; K point is the intersection point of L m and U=95%.

(3) Induction ratio: Point C can be determined from this.

(4) The indoor residual heat Q is respectively borne by Q M1 and Q M2, so the cooling capacity of the primary air treatment box: the cooling capacity of the inner coil tube.

(5) According to the primary air volume and induction ratio and product samples provided by manufacturers to select the appropriate type of cold beam, and according to the thermal efficiency of the cold beam to the heat exchanger cooling capacity check.

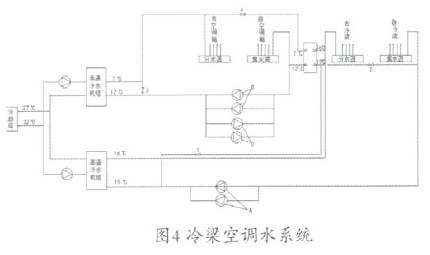

3.2 Control of cold beam water distribution system

Water distribution system is an important part of cold beam system. Take the active cold beam as an example, because the temperature of the chilled water in the air conditioning box and the chilled water in the cold beam is different, there is a big difference, so two sets of water chillers are needed, namely high temperature water chillers and low temperature water chillers. Considering the better refrigeration effect, the supply and return water temperature of the two sets of water chillers are: 7℃/12℃, 16℃/19℃. According to the control chart of the cooling beam water distribution system in the literature, it is found that if the low temperature water unit fails, it can only replace the low temperature water unit with the high temperature water unit, and its own loss

To the due role, that is, only to the cooling water of the air conditioning box and not to the cooling water of the cooling beam. After improvement, no matter which chiller failure, can ensure the stable operation of the system. Its principle is shown in Figure 4:

Under normal circumstances, the two units are normal operation, valves (1)(2)(3)(4) are closed, circulating pump A, B open; When the low temperature chiller is faulty, the high temperature chiller is used to drive the operation of the whole system. The valve (2)(3)(4) is opened, the valve (1) is closed, and the circulating pump A and C are opened; When the high temperature chiller is faulty, the low temperature chiller is used to drive the operation of the whole system. The valve (1)(4) is opened, the valve (2)(3) is closed, and the circulating pump A and B are opened.

Under normal circumstances, the high temperature water pump will be 16℃ high temperature chilled water into the cold beam, in the room to absorb heat

After, the return water temperature rises, through the return pipe into the water collector. Cold beam water supply pipe is installed with an electric control valve, the room temperature controller control the opening degree of the electric control valve, when the room temperature is higher than the set value, increase the valve opening degree; Lower than the set value, reduce the valve opening degree to maintain a constant temperature in the room. After the induced fresh air is processed by the air processor, it is sent to the room through the cold beam. Because the number of people working in the room changes little and the required fresh air volume is basically constant, so the blower uses fixed frequency operation.

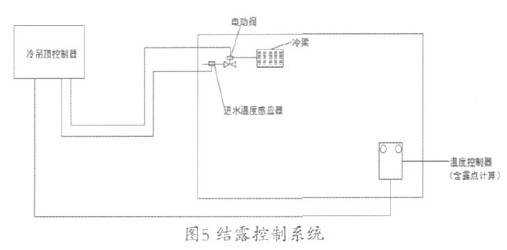

3.3 Cold beam condensation prevention control system

In order to ensure that the cold beam does not produce condensation, the relative humidity of indoor air is generally controlled below 50%, and the condensation prevention and control system should also be installed, as shown in Figure 5:

Into LengLiang cooling water inlet temperature sensors measured temperature t1, temperature controller by the indoor air temperature t2, humidity, and then calculate the dew point temperature, t1 and t2 in cold condole top controller compared to deviation e = t1, t2, when deviation e is negative deviation, the electric valve closed, stop induced air cooling, indoor temperature, There will be no condensation at the cold beam coil.

3.4 Combination of cold beam air supply system and other systems

In large office areas, the cold beam system + fan coil system can be used to eliminate the cold and heat load in the building area and provide sufficient fresh air for the office area. In the outer area, the floor type fan coil unit can be used to eliminate the heat gain of the envelope structure such as Windows. At the same time, the exhaust air can also be pretreated by the total heat energy recovery unit (cooling and dehumidification in summer, heating and humidification in winter), and the processed fresh air is sent to the air conditioning room on each floor, and sent to the office area by the cold beam system.

Four, summary

Due to the installation convenience, energy saving, providing more comfortable and healthy indoor air quality and other advantages of cold beam system, more and more has been promoted and applied. According to the installation environment to determine the best position of cold beam installation, so that the air distribution more in line with the human body comfort requirements. The primary air of the cold beam system can be the whole fresh air or a mixture of fresh air and partial return air.

The cooling beam system has obvious energy saving effect. As the water supply temperature of chilled water is increased, the COP value of the cooling coefficient of the chiller is correspondingly increased. The relevant test data show that when the cooling water outlet temperature is kept constant, the cooling capacity will decrease by about 5% and the COP value of the cooling coefficient will decrease by about 3% when the chilled water outlet temperature of the water-cooled screw unit decreases by 1℃.

Due to the small air outlet speed of the cold beam and relatively weak air circulation, the indoor cooling speed is slow and the cooling delay is long, so it is necessary to start up and run in advance. The initial investment is high, and condensate will be generated when out of control. Therefore, how to effectively detect, avoid and control the condensation problem of the ceiling under the state of refrigeration and how to deal with condensate once out of control is an important issue affecting the development of cold beam. Cold beam system is a new subject, need to constantly discuss and improve in practice, deal with the shortcomings of cold beam, cold beam development prospects will be better and better.